OUR PRODUCTS –

OUR INNOVATIONS

Equip your workforce with Aero-Motive® tool supports for a safer and more efficient industrial environment. Enter the world of our innovative solutions.

Application areas

At a glance

»Aero-Motive® products provide the right solution for the right application, for every industry while creating long-term value through lasting performance. Our commitment to our customers is strong, and we aim to meet the expectations of our valued customers by providing efficient and valuable solutions.«

Installation Simplified

Setting Up Your Aero-Motive® Tool Support Solutions

Crafted for Distinction

Feature Identifiers

Our products are defined by a series of unique features that ensure highest standards of industrial utility and ergonomic design.

Tension can be adjusted easily to match the weight of the load while controlling the retraction speed.

Learn more

This feature allows the unit to be safely mounted or secured within applications, upper mounts can be fixed allowing minimum rotational freedom or best designs allow a 360° rotational freedom for unit movement.

This is an internal mechanism which prevents a load from falling in the event that a unit loses tension or a power-spring breaks.

Facilitates quick and safe tool/load changeover without the risk of cable fly-back.

Enables manual lock to be engaged or disengaged using a cam/lever arm, operated by a conveniently placed floor-level handle.

Plug and play feature allows cable replacement to be done easily while balancer is still in service.

Power springs are contained in cassettes to allow easy and safe handling.

Special cam design which allows cable locking at the desired position, ratchet is unlocked with a simple tug of the cable. Ratchet is always ON by design.

Same as ratchet lock “ON”, but ratchet lock function can be manually engaged or disengaged. Ratchet functionality is disabled in “OFF” mode.

Added safety feature to eliminate cable fly-backs caused by cable failures or accidental tool detachments.

Automatically prevents damage to power spring in the event of reverse winding.

Drum is coated with WearGuard™ epoxy to extend cable and drum life in harsh environments.

Designed specifically to extend Cable Life as cables are pulled at different angles within applications for different tasks. Best Cable Guides employ Roller Guides as to eliminate complete Friction between Cable and Cable Guide.

Feature Identifiers for External Tension Adjustment

This system employs a spring loaded knob and a positive manual ratchet design. To add tension, turn ergo knob clockwise or towards “+” until desired tension is reached. To remove tension, pull and turn the knob counterclockwise one ratchet at a time.

This system employs a spring loaded and positive spring loaded ratchet cam design. To add tension, turn ergo knob clockwise or towards “+” until desired tension is reached. To remove tension, hold ergo knob whilst pushing on the cam – the knob will turn counterclockwise one ratchet at a time.

This is an internal mechanism which prevents a load from falling in the event that a unit loses tension or a power-spring breaks.

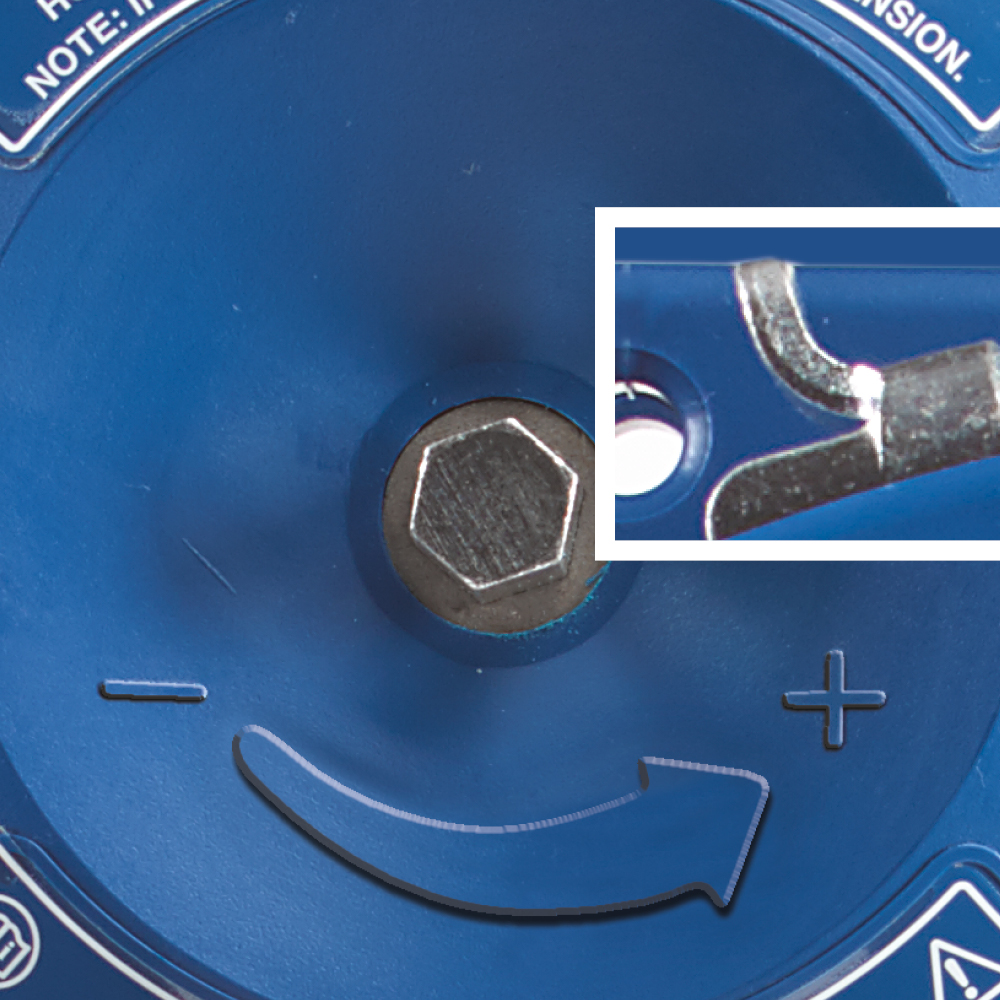

This system allows the cam to manually lock in place at a desired position by means of a lock lever. To add tension, insert a hex key into the cam and turn it clockwise or in the direction of the “+” sign. Do not release the hex key until the cam is locked in place by the lock lever.

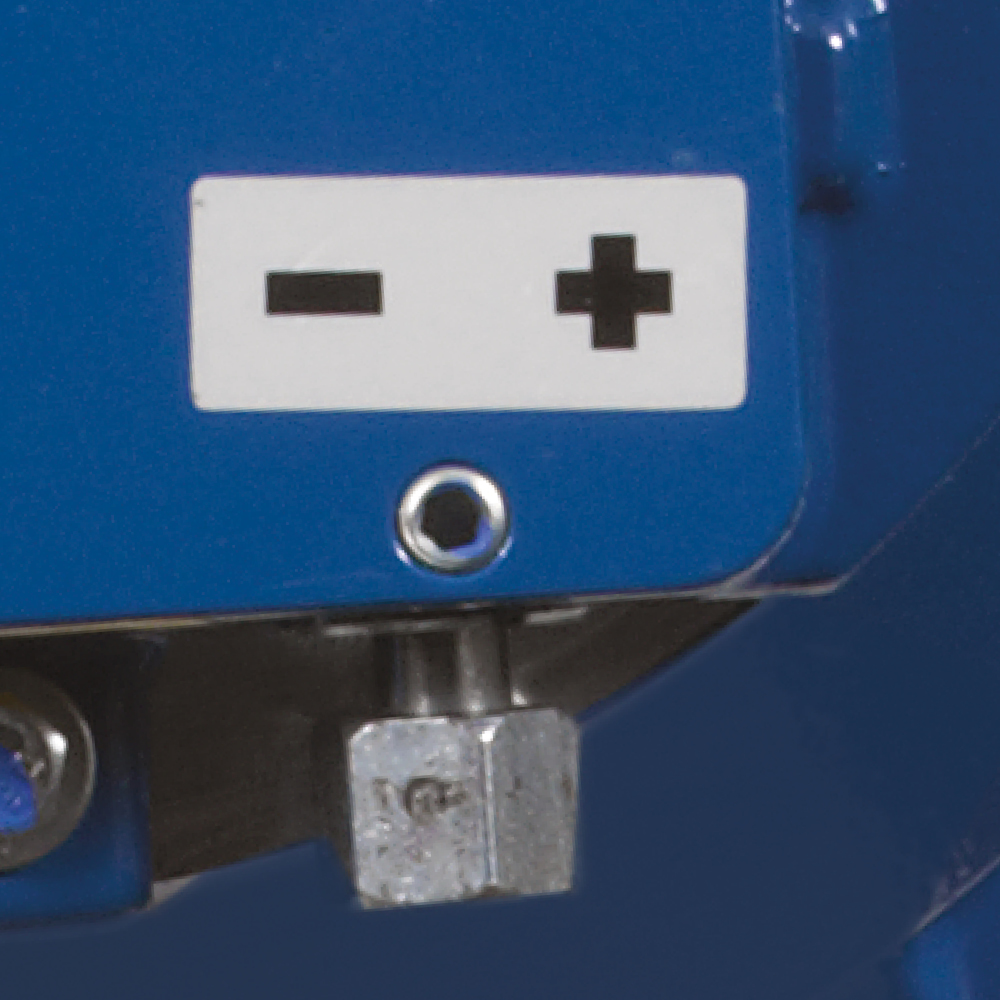

Designed to easily add or remove tension for loads of up to 375 lbs (170 kg) using nut runner tools. Add tension by simply turning bolt clockwise or in “+” direction. Remove tension by turning bolt counter-clockwise or in “–” direction.

This system works by locking the main shaft in place by exerting pressure which is evenly dispersed around the circumference of the main shaft. Add tension by simply turning main shaft counter-clockwise or in the “+” direction. To remove tension, first hold main shaft by means of a manual key and then press on the spring clutch lever to allow rotation of shaft.

Add tension by simply turning main shaft counter-clockwise or in the “+” direction until desired tension is reached. To remove tension, first hold main shaft by means of a manual key and then push on the Cam Lever to allow rotation of shaft in the “–” or clockwise direction.

This design allows the unit to build friction instead of building tension. It builds up friction as the cable is pulled out of the unit. Simple tension adjustment using a flat driver or a coin. To achieve desired Ergonomics, add friction by turning the shaft in “+” direction or remove friction by turning the shaft in “–” direction.

Our Product Services

Repair parts and kits for long-lasting products

Aero-Motive® products are developed and manufactured with the highest quality standards. The sustainability of our products plays an important role in every life cycle. We take great care to ensure that the vast majority of our series can be serviced and also stock repair parts for this purpose.

If you need a specific spare part, you can contact us at any time. We will help you to get back up and running as quickly as possible.

Customized Solutions for your applications

We offer you the option of customizing our products to meet your individual requirements. This includes, for example, a different housing color and labeling according to your specifications.

Contact us and we will discuss your modification request with you.